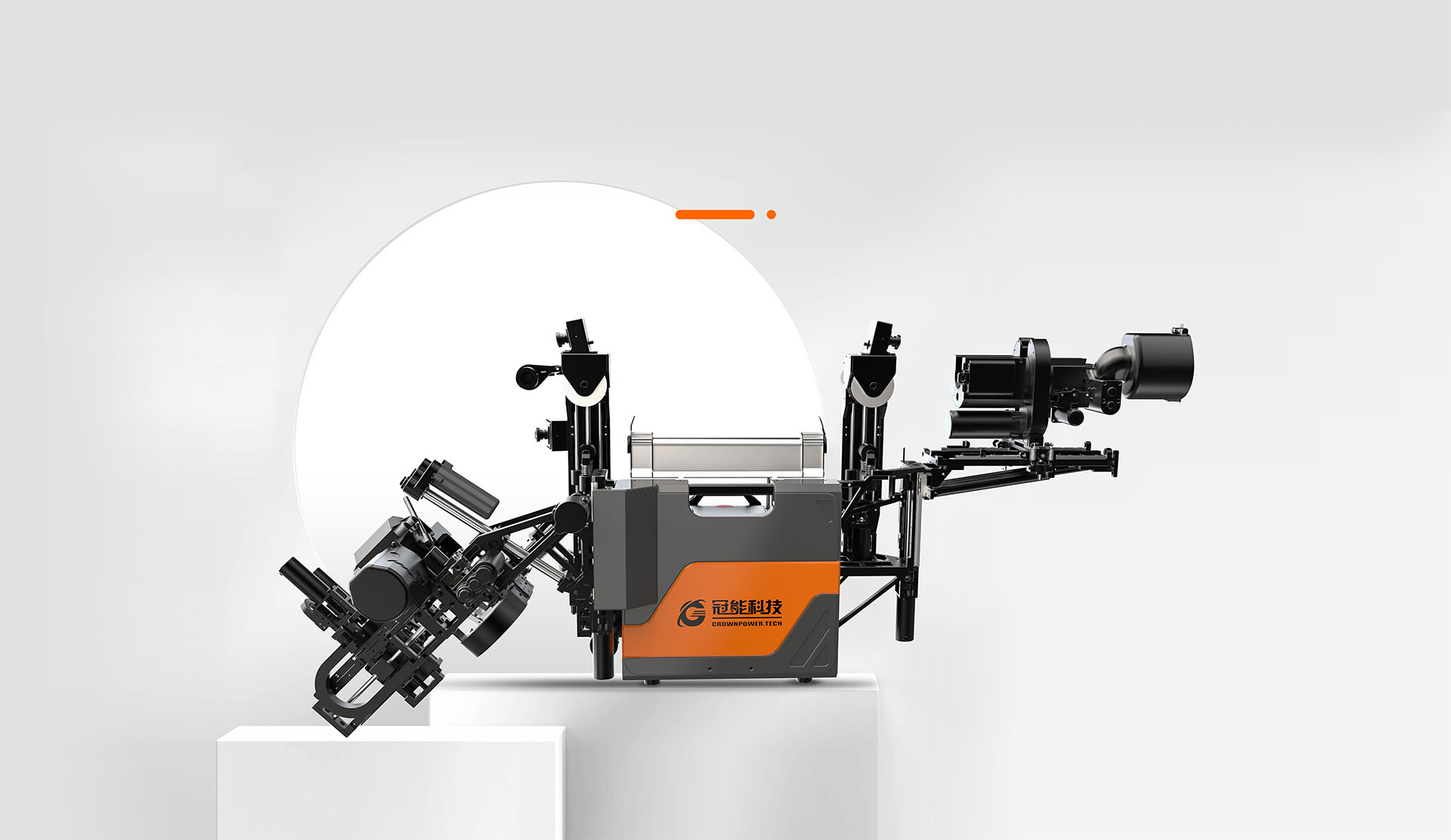

| Live Working | EJH-10 |

|---|---|

| Product weight | 30kg (66lb) |

| Voltage level | 10kV |

| Conductor height | ≤15m |

| Communication modes | Radio & WLAN |

| Travelling speed | 4-6m/min |

X7 - AI

Lead Connection Robot

- Live - working Robotic System

- Intelligent Operation

- All - scenario Operations

- Cost Efficiency & Performance Boost

Technical Parameters

| Product dimensions | 125cm×46cm×53cm |

|---|---|

| Online type | Automatic online |

| Applicable wire diameter | LGJ-50-LGJ-240(11.6mm-22.4mm) |

| Conductor height | ≤15m |

| Communication distance | >200m (Unobstructed) |

| Climbing angle | ≤30° |

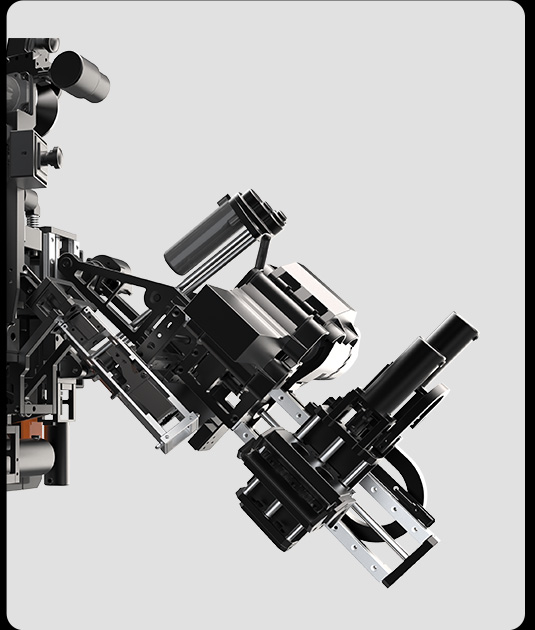

Component display

Wire Stripping Robotic Arm

Lead-in Wire Robotic Arm |

|

Core Functions

LIVE-WORKING ROBOTIC SYSTEM

LIVE-WORKING ROBOTIC SYSTEM

The machine employs electromagnetic shielding technology, rapid equipotentialization, and real-time potential detection circuits to ensure safe live-line operations in high-altitude, high-voltage, and strong electric field environments. Furthermore, by integrating an automated online platform, operators can perform tasks without the need for climbing or getting close to live electrical components.

INTELLIGENT OPERATION

INTELLIGENT OPERATION

The system integrates multi-modal perception technology to achieve multi-dimensional monitoring of the working environment and equipment status. Combined with deep learning model training, it enables accurate identification of complex power lines and precise prediction of potential risks.

The robot can autonomously select optimal solutions, accurately execute live-line connection tasks, and dynamically adjust strategies based on real-time conditions, achieving fully automated operation throughout the entire process.

ALL-SCENARIO OPERATIONS

ALL-SCENARIO OPERATIONS

The robot features a compact and lightweight design with user-friendly operation, breaking free from terrain and space constraints. It eliminates the need for cumbersome preparations and large live working vehicle coordination, enabling highly efficient live-line connections in any scenario.

COST EFFICIENCY & PERFORMANCE BOOST

COST EFFICIENCY & PERFORMANCE BOOST

Compared with traditional live-wire connection solutions, the robotic system delivers 30%-50% reduction in service costs, 60%-80% lower procurement costs.

Operation Procedure

Insert the lead wire into the traction fixture

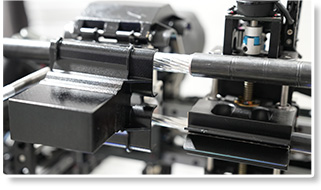

Install the parallel groove clamp

Robot Automatic online

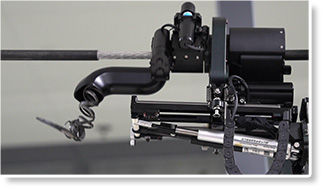

The robot moves to the wire stripping position

The stripping arm starts to strip the wire

Pull the lead wire into position

Take out the lead wire

Lift the parallel groove clamp to the wire stripping position

Tighten the bolts of the parallel groove clamp

Robot goes offline automatically

Service Site